Transform Operations With a Real-Time Coal Stockpile Monitoring System

Our Coal Stockpile Monitoring System utilizes advanced 3D scanning technology to get precise, real-time tonnage data, optimizing everything from procurement and safety to operational uptime.

Risks of Operating Without a Modern Coal Stockpile Monitoring System

Managing bulk coal inventory without a reliable coal stockpile monitoring system is a high-stakes balancing act where small inaccuracies cascade into significant financial and operational consequences.

Operational Failures

Production Halts & Runouts

An unexpected coal shortage is a catastrophic failure. Without an effective coal stockpile monitoring system, power plants risk blackouts and factories face production halts, leading to astronomical financial losses for every hour of downtime.

Cascading Inefficiencies

These runouts are often the result of poor data from an inadequate or non-existent coal stockpile monitoring system. Inaccurate consumption forecasts lead to flawed procurement, creating a reactive and inefficient operational rhythm.

Financial Risks

Inaccurate Surveys & Write-Offs

Infrequent manual surveys lead to "phantom inventory," where book values don't match reality. A modern coal stockpile monitoring system prevents the massive inventory write-offs that shock stakeholders and impact financial stability.

Tied-Up Capital

Conversely, over-purchasing based on bad data ties up millions in working capital. An accurate coal stockpile monitoring system frees this capital for critical investments instead of letting it sit dormant in a pile.

Safety & Compliance Hazards

Extreme Dangers of Manual Surveys

Sending personnel to walk on unstable stockpiles is a peril that a remote coal stockpile monitoring system completely eliminates. You remove the risks of slips, falls, and engulfment, reducing liability and insurance premiums.

Regulatory Scrutiny

Inaccurate reporting can lead to fines and legal action. Implementing a state-of-the-art coal stockpile monitoring system demonstrates proactive, safe, and accurate management practices essential for compliance.

Supply Chain Chaos

Inefficient Procurement & Logistics

When you don't know your exact inventory, you can't procure intelligently. A real-time coal stockpile monitoring system ends costly emergency purchases and prevents expensive demurrage fees for waiting ships and trains.

Missed Opportunities

A lack of precise inventory data prevents strategic purchasing. Our coal stockpile monitoring system provides the data needed to buy in bulk when market prices are low, locking in savings and stabilizing your supply chain.

Hyperion: A Smarter Coal Stockpile Monitoring System

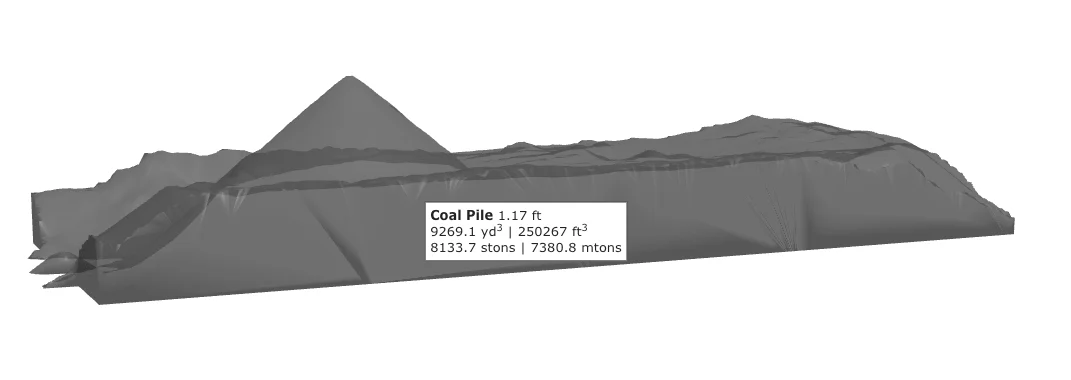

The Hyperion Coal Stockpile Monitoring System is the definitive solution to these challenges, fundamentally changing how you see and manage your most critical asset. We turn your static coal stockpiles into dynamic, data-producing digital twins.

By replacing dangerous and error-prone manual methods, our system provides the data-driven foundation for operational excellence. It transforms inventory measurement from a reactive task into a proactive source of strategic value.

How Our Coal Stockpile Monitoring System Works

Hyperion provides a seamless, end-to-end coal stockpile monitoring system for complete visibility and control, delivering actionable intelligence directly to your team.

Data-Driven Certainty

Visualize the difference: sporadic manual surveys versus the continuous, accurate data stream from the Hyperion coal stockpile monitoring system.

Automated 3D Volumetric Scanning

The core of our coal stockpile monitoring system is industrial-grade 3D scanning technology (LiDAR) that generates a complete point cloud of your stockpile surface, ensuring survey-grade accuracy automatically.

Safety First, Data Always

By removing personnel from the piles, you eliminate significant safety risks. This automated system works 24/7, in any weather, ensuring you have a consistent stream of data exactly when you need it.

Real-Time Data & Cloud Platform

The raw scan data is instantly processed in our secure cloud platform. Our coal stockpile monitoring system applies your specific bulk density factors to convert volume into accurate tonnage.

Anywhere Access to Actionable Insights

Access up-to-the-minute tonnage and consumption rates from any device. Our intuitive dashboard makes it easy to prevent runouts, schedule deliveries, and make smarter purchasing decisions on the spot.

Automated Alerts & Reporting

Our coal stockpile monitoring system allows you to set custom alerts for low tonnage, rapid depletion, and fill events, moving you from reactive to proactive management.

Effortless, Accurate Reporting

Automate inventory, compliance, and financial reports. Free your team from hours of manual spreadsheet work, eliminate human error, and deliver consistent, accurate reports with the click of a button.

Multi-Pile & Multi-Site Management

Our platform is designed for the scale of modern industry. The Hyperion coal stockpile monitoring system lets you view your entire inventory—across piles, grades, and locations—from one dashboard.

A True Enterprise View

This centralized control provides an unprecedented, enterprise-level picture of your company's most critical asset, enabling smarter strategic decisions and standardized metrics across all facilities.

Applications for Our Coal Stockpile Monitoring System

The Hyperion coal stockpile monitoring system is not a one-size-fits-all solution. It delivers targeted, measurable value across a wide range of industries where coal is a mission-critical component.

Power Generation

For coal-fired power plants, fuel security is synonymous with grid security. Our coal stockpile monitoring system ensures a continuous, reliable fuel supply to prevent costly downtime.

Optimizing the Blend

By accurately tracking multiple stockpiles of different coal grades, operators can optimize blending strategies, manage heat rates (BTU), control emissions, and improve overall boiler efficiency.

Steel & Cement Manufacturing

In these industries, coal is a critical chemical input. A precise coal stockpile monitoring system is essential for managing inputs like coking and thermal coal to ensure product quality and process stability.

Ensuring Process Stability

Hyperion provides the data needed to ensure a consistent feed to furnaces and kilns. This improves supply chain visibility, allows for accurate consumption tracking, and leads to superior cost control.

Ports & Terminals

Ports and terminals manage massive stockpiles for import and export. An effective coal stockpile monitoring system is paramount for efficiency and accuracy in this high-volume environment.

Maximizing Throughput

Hyperion allows operators to optimize vessel loading, minimize demurrage fees, and provide accurate, auditable data to all stakeholders. It is key to managing custody transfer with confidence.

Mining Operations

At the source, accuracy is critical. Mines need a reliable coal stockpile monitoring system to track production from the moment it leaves the pit for effective financial and operational planning.

From Pit to Port

Hyperion enables mines to accurately track run-of-mine (ROM) production, manage graded stockpiles, and precisely reconcile mined tonnage against sales contracts, improving planning and forecasting.

Ready to Upgrade Your Coal Stockpile Monitoring System?

Stop estimating and start knowing. Eliminate safety risks, end costly operational surprises, and unlock the full value of your inventory. Discover how the Hyperion coal stockpile monitoring system can transform your operations.

Request a Consultation

Do not hesitate to reach out. Just fill in the contact form here and we’ll be sure to reply as fast as possible.

Message us

info@altamusinc.com

+1 352-283-8003