Inventory Accuracy for RMX Plants with Hyperion LiDAR

An in-depth analysis of how Hyperion's scanning technology transforms inventory management at our client's RMX plant, revealing significant discrepancies and demonstrating a tangible return on investment against traditional ticketing methods.

- ✓ High material throughput: Frequent deliveries and draws complicate tracking.

- ✓ Multiple aggregate types: Need for precise monitoring for each material type.

- ✓ Operational complexity: Constant balance between theoretical, physical, and production inventory needs.

The Challenge at Ocala RMX Plant

A High-Volume Environment

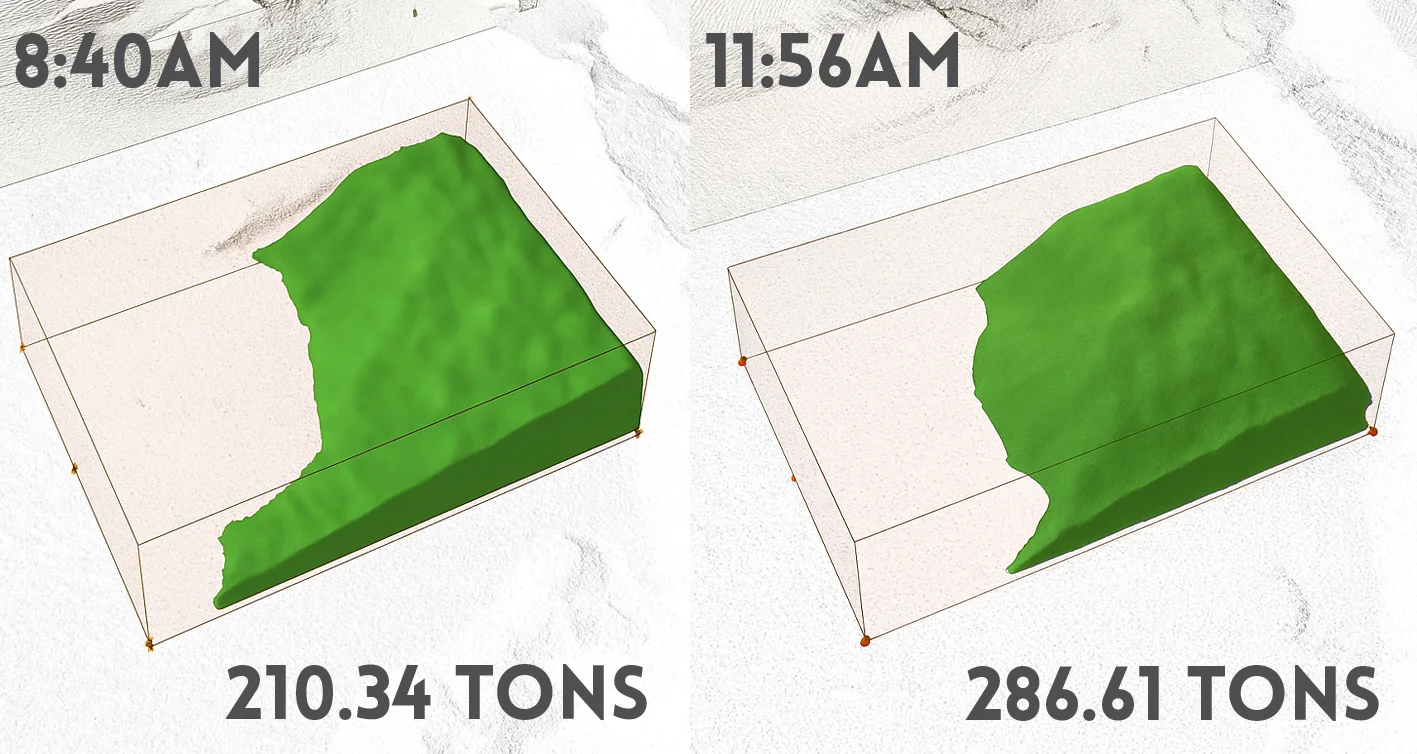

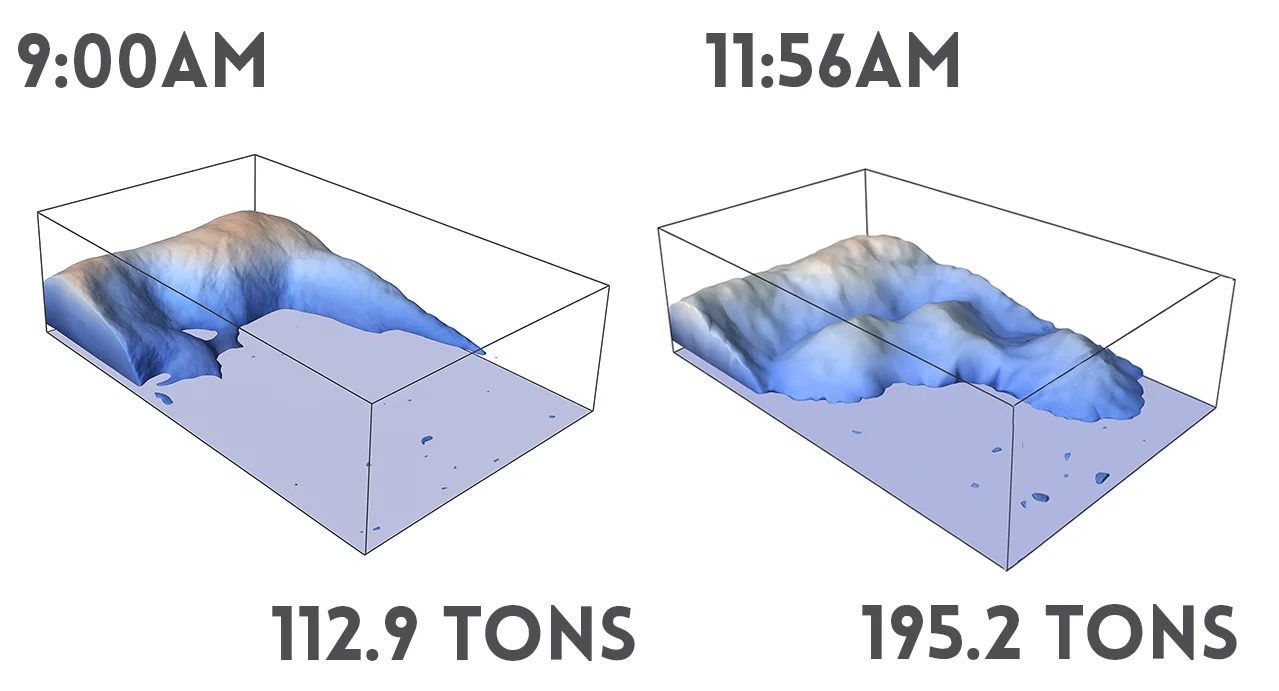

This RMX is a high-volume ready-mix concrete plant that handles a constant flow of limestone and sand. The rapid turnover of these materials presents a significant challenge in maintaining an accurate inventory. The exclusive reliance on truck tickets for inventory tracking introduces variables such as moisture, scale calibration, and material flow inconsistencies, which generate costly discrepancies.

This dynamic environment served as the ideal testing ground to evaluate an advanced measurement solution like Hyperion, where the precision of LiDAR-based scanning could be directly compared to ticket-based accounting to uncover inefficiencies and improve decision-making.

Comparison: Ticketing System vs. Hyperion

| Category | Traditional Ticketing System | Hyperion Scanning System |

|---|---|---|

| Accuracy |

Depends on truck scales, moisture changes, and inconsistencies.

|

Accuracy within 5%. Consistent volumetric measurements.

|

| Financial Impact |

Discrepancies lead to hidden losses. E.g., >$160k gaps observed.

|

Identifies leaks between theoretical vs physical inventory.

|

| Consistency |

Dependent on operators and manual entry. High variability.

|

Automated scans ensure consistent, unbiased data.

|

| Scalability |

Local data silos, hard to standardize across sites.

|

Cloud-ready. Integrates with SAP/JD Edwards.

|

Data Analysis: Inventory Measurement

Over a three-month period, theoretical, physical, and Hyperion scan data were compared to identify discrepancies.

Inventory Comparison - March 2025

Inventory Comparison - April 2025

Inventory Comparison - May 2025

Gain/Loss Analysis - May 2025

Hyperion Cost Analysis

Initial Investment

Total cost covering hardware, network setup, installation, and first month of service.

Recurring Costs

Predictable operational costs for 24/7 accuracy.

Control Tests and Accuracy

Results from isolated control tests demonstrating remarkable consistency against truck tickets.

Control Test 1 (05/08/2021)

Tickets: 81.16 st

Hyperion: 76.23 st

Control Test 2 (05/21/2025)

Tickets: 85.82 st

Hyperion: 82.3 st

Conclusion: A Clear and Measurable Advantage

The study at the Quikrete Ocala RMX plant conclusively demonstrates the advantages of Hyperion over traditional ticketing systems. While ticket-based management is prone to cumulative errors, Hyperion provides direct, high-precision measurements that reflect the true state of inventories.

By adopting Hyperion, operations gain a scalable and reliable inventory tracking method that surpasses the ticketing system in both accuracy and efficiency, transforming inventory data into actionable business intelligence.

Request a Consultation

Do not hesitate to reach out. Just fill in the contact form here and we’ll be sure to reply as fast as possible.

Message us

info@altamusinc.com

+1 352-283-8003