Advanced Stockpile Inventory Management for Cement Operations

Leverage Hyperion's automated system for precise stockpile monitoring, waste reduction, and maximum profitability. Trusted by industry leaders.

The High Cost of Inaccurate Stockpile Inventory Management

In the fast-paced cement industry, effective stockpile inventory management is the cornerstone of profitability. However, traditional methods are notoriously unreliable, creating hidden costs across the entire operation.

Operational Disruptions from Poor Stockpile Monitoring

Guesswork leads to unexpected material shortages that halt production, leaving trucks, drivers, and plant operators idle. This downtime doesn't just stop the flow of concrete; it creates a ripple effect, delaying projects, frustrating customers, and damaging your reputation for reliability. Every hour of stoppage is a direct loss of revenue and an indirect hit to your brand's credibility.

Financial Burdens of Inefficient Inventory

The financial implications of poor inventory data are substantial. To avoid shortages, many operators overstock, tying up significant working capital in static piles of aggregate. This excess inventory also increases carrying costs and is susceptible to waste and degradation. More importantly, understanding your inventory allows you to buy when the market is cheap or to jump on a good deal because you know you have the capacity in your storage area.

Strategic Blind Spots in Stockpile Management

Without a precise, real-time understanding of on-hand inventory, businesses operate with a high degree of uncertainty. This lack of visibility is a critical vulnerability, preventing effective procurement strategies, optimized production scheduling, and confident financial planning. You can't manage what you can't measure, and this strategic blind spot in your stockpile inventory management exposes your operation to risks that directly impact long-term profitability and growth.

The Hyperion Difference: Data-Backed Performance

Our system isn't just about estimates; it's about delivering verifiable, survey-grade data that transforms your stockpile inventory management.

Variance vs. 3rd Party Terrestrial Survey

Automated Inventory Visibility

Complete Scan & Processing Time

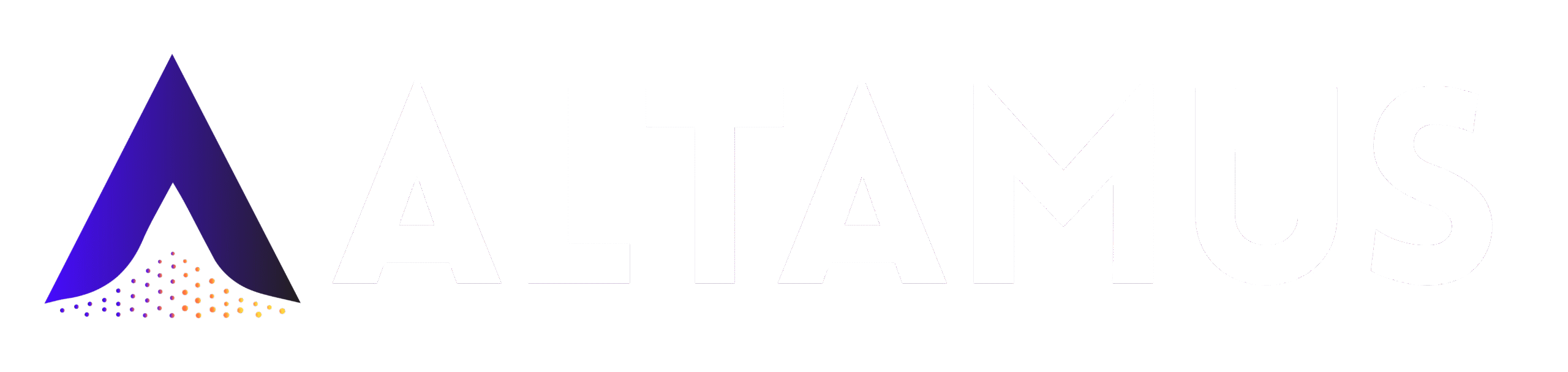

Case Study: A Cement Plant's Stockpile Inventory Management

Precision Inventory at the Newberry Plant

At their Newberry, FL facility, A Cement Plant needed to verify the accuracy of their indoor coal stockpile inventory. The challenge was to get a precise measurement without disrupting operations and to validate it against a trusted, independent standard. Traditional methods were too slow and intermittent to provide the daily insights needed for efficient operations.

Using four permanently installed Altamus EOS2 LiDAR scanners mounted on overhead trusses, the Hyperion system performed a complete scan and processed the data in under 20 minutes. This was executed during normal operations, requiring no downtime. The result was a mass estimate that achieved undeniable survey-grade accuracy, providing the cement plant with the confidence to manage their inventory with precision.

Demonstrates a 0.55% variance relative to a certified third-party terrestrial survey.How Our Stockpile Monitoring Works

Our automated stockpile inventory management system is an end-to-end solution that transforms your physical materials into precise digital data in three simple steps.

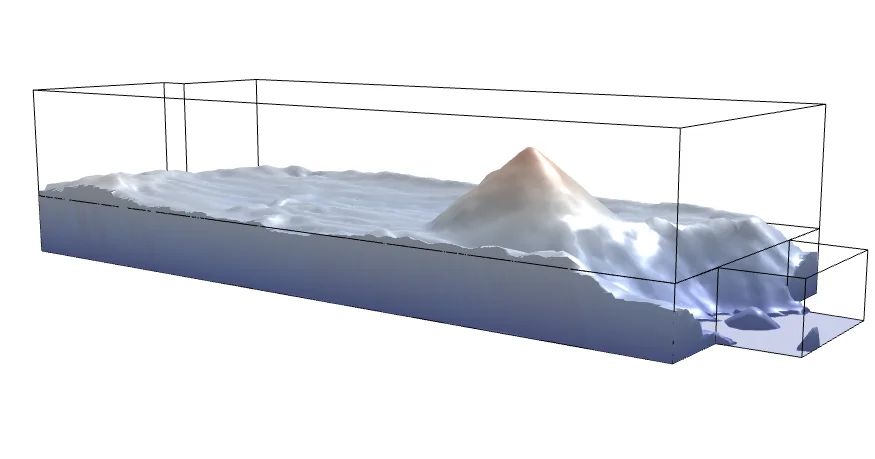

Automated Data Capture

Permanently installed, eye-safe Class-1 LiDAR scanners, like our EOS2 model, are strategically placed above your stockpiles. These scanners can be triggered on a schedule or on-demand via a simple browser interface. They emit thousands of laser points per second, creating a dense and comprehensive "point cloud" that maps the exact surface of your material piles with millimeter-level precision, capturing every peak and valley without the safety risks or operational downtime of manual surveys.

Intelligent Cloud Processing

The captured point cloud data is automatically uploaded to the Hyperion cloud platform. Our proprietary software then gets to work. It composites the data from multiple scanners, filters out noise and equipment, and applies advanced algorithms like Poisson surface reconstruction to generate a seamless, highly accurate 3D mesh of the stockpile's surface. This digital model is then used to compute the precise volume.

Actionable Insights on Demand

Within minutes, the results are available on your Hyperion dashboard. You can view the 3D model of your stockpile, see the precise volume, and, by applying your material density, get an accurate weight calculation. This data is available 24/7 from any device, allowing for reliable daily or even per-shift inventory reconciliation. This level of stockpile monitoring sets a new industry standard.

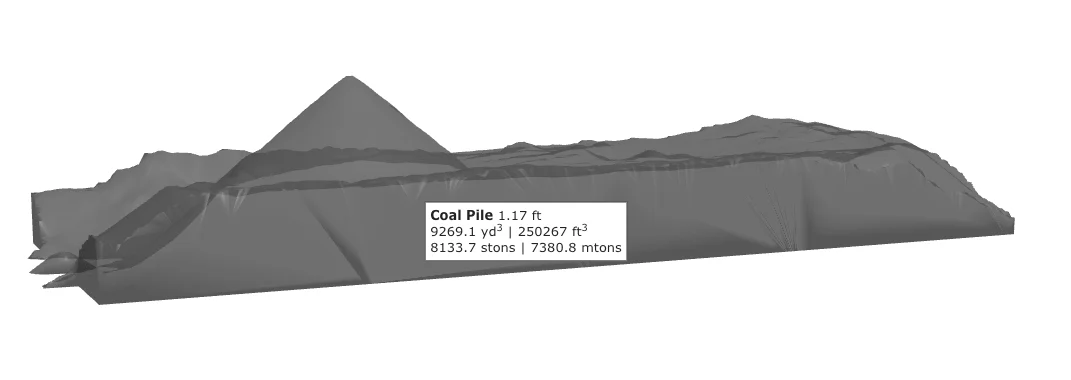

Visualizing Your Stockpile Monitoring Data

Hyperion transforms complex LiDAR data into clear, intuitive visualizations, giving you an unparalleled understanding of your inventory.

Accurate 3D Models

See your exact stockpile shape and volume with our automatically generated 3D mesh models. This isn't an estimation; it's a digital twin of your physical inventory, allowing you to identify irregularities, plan reclamation, and verify deliveries with complete confidence.

Detailed Height Maps

Instantly understand the distribution of material within your piles. Our color-coded height maps make it easy to spot high and low points, monitor pile geometry, and ensure safe and efficient material handling by front-end loaders. This level of detail is critical for optimizing space and preventing material segregation.

The Hyperion Advantage in Stockpile Inventory Management

Our system provides more than just data; it delivers actionable intelligence that drives smarter business decisions and a stronger competitive edge.

Financial Control & Reduced Waste

Stop tying up capital in excess inventory. With an accurate, real-time view of your stockpiles, you can shift to a just-in-time ordering strategy, reducing carrying costs and minimizing material degradation or loss. Eliminate costly end-of-month write-offs and gain a true, auditable picture of your assets for more accurate financial reporting.

Enhanced Site Safety

Manual stockpile surveys are inherently dangerous, requiring personnel to walk on or near unstable piles of material. The Hyperion system completely automates this process. Our permanently mounted scanners eliminate the need for surveyors on the ground, drastically reducing the risk of slips, falls, and other site accidents associated with inventory measurement.

Optimized Operational Workflow

Free your team from the time-consuming and inaccurate task of manual measurements. With automated scans and instant data processing, your plant managers and procurement teams can focus on what they do best. Proactive low-stock alerts prevent production stoppages, ensuring a smooth, continuous flow of materials to your batch plant and reliable service to your customers.

Data-Driven Decision Making

The Hyperion dashboard is more than a measurement tool—it's a business intelligence platform. Analyze historical consumption trends to identify patterns, forecast future demand with greater confidence, and optimize your supply chain. Share accurate, consistent data across departments—from operations to finance—to ensure everyone is working from the same numbers.

Ready to Achieve Precision in Your Stockpile Inventory Management?

Contact us today for a personalized demonstration and discover how Hyperion can bring survey-grade accuracy, efficiency, and profitability to your operations.

Request A Consultation

Do not hesitate to reach out. Just fill in the contact form here and we’ll be sure to reply as fast as possible.

Message us

info@altamusinc.com

+1 352-283-8003